2020/11/06(金)

Hiroko Sato, Ph.D., COO, Board Member, UniBio CORP.

Safest, cheapest, and fastest way to develop regenerative medicine materials using plant biotechnology

Hiroko Sato, Ph.D., COO, Board Member, UniBio CORP.

[Summary]

<Our business and our contribution to society>

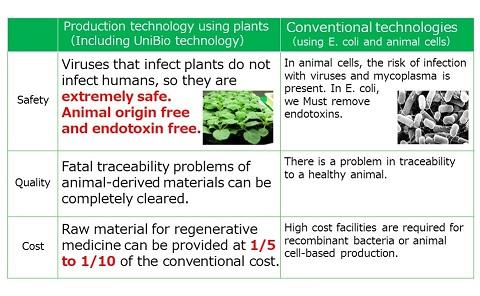

We at UniBio are developing useful proteins as regenerative medicine materials with confidence, safely, and efficiently using plant biotechnology. For example, growth factors are some of many useful proteins that occupies the majority of growth medium, serum, and reagent markets. Most of such growth factors are (1) expensive imports, and (2) are expressed from animal or bacteria, whose risk of contamination with pathogens such as virus, bacteria, or endotoxin cannot be eliminated. In order to solve those problems from the roots, we are developing a technology to manufacture various growth factors safely and efficiently. By using plants to develop and manufacture growth factors, we are able to not only ensure the safety of our products that other production technologies cannot match, but also implement high-mix low-volume production, and manufacture proteins with a dramatically low cost due to elimination of many production processes.

Our technology contributes to acceleration of R&D speed for researchers and regenerative medicine (RM) providers/companies who purchase materials. Also, we can provide safety of final RM products and cost savings of materials that can be passed on to the reduction of medical costs. In this way, we can contribute to the future of patients, the final end user, being able to receive treatment with confidence.

<Overview and advantages>

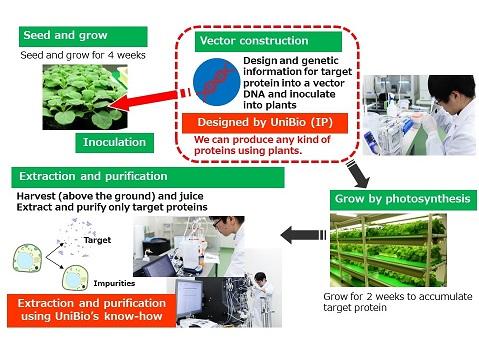

We utilize plant transient expression technology, which does not depend on the use of GMOs. We construct plasmid vectors, inoculate plants with vectors, harvest the plant two weeks after inoculation, extract, and purify the desired proteins. These processes enable us to produce multiple growth factors in a short time. Thus, we can produce all materials, including many growth factors, needed to construct a whole organ with plants, which are very safe to use. Stepping up from this RM business, we are planning to develop cultured meat, bioinks for 3D bioprinters, pharmaceuticals, RM products, and vaccines to fight infectious diseases such as COVID-19.

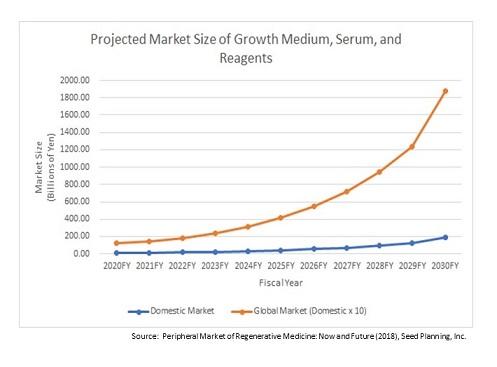

<Markets>

The RM market is expected to grow rapidly starting the year 2030, with the proportional growth of the peripheral markets that include growth medium, serum, and reagents. Out of the RM peripheral market, the size of the growth factor market (our first target) is expected to grow up to approximately 580 billion Japanese yen, and we will grasp the commanding share. After this, we are planning to enter into the larger markets such as cultured meat and vaccines.

[Profile]

March 2006: Graduated with Ph.D. in economics from Niigata University Graduate School of Modern Society and Culture, majoring in the international society and culture studies.

August 2007: Employed in the New Energy and Industrial Technology Development Organization (NEDO), appointed as a NEDO fellow dispatched to Niigata TLO Inc. in charge of academia-industry cooperation.

March 2011: Founded UniBio Corporation with the current CEO.